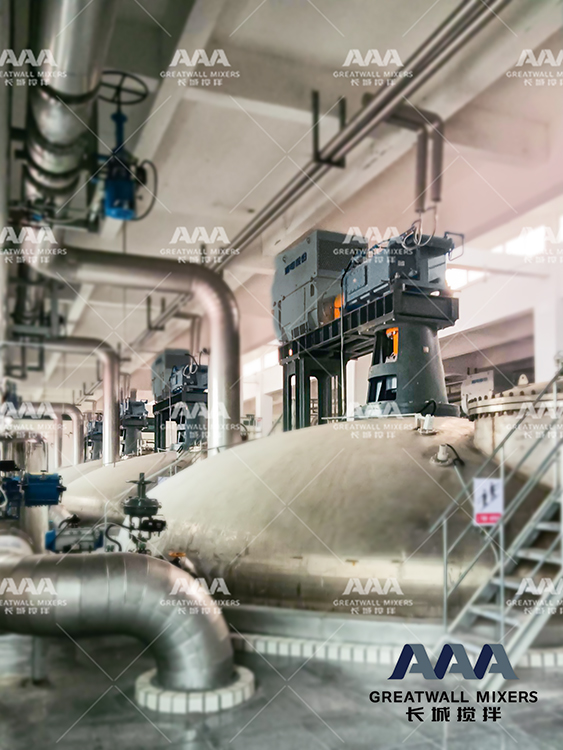

In January 2024, the service engineer of Greatwall Mixers provided on-site commissioning services for agitators of a bioengineering project in Henan province, China. The core equipment of these agitator is the fermentor, mainly used for producing Lysine.

During the design phase, the design team at Greatwall Mixers fully considered the customer's requirements for oxygenation and uniform dispersion of the culture medium. Taking into account parameters such as working temperature, pressure, medium characteristics, density, and viscosity inside the tank, the design team conducted multiple rounds of calculations, verification, and simulations. Eventually, they adopted a combination of defoaming impellers, wide-blade propellers, and parabolic disc turbine impellers. This combination has been widely applied in fermentation tanks with excellent results.The advantages of this combination lie in the fact that the top foam-eliminating impeller effectively removes a large amount of foam covering the liquid surface. This type of impeller is a high-speed one, and the centrifugal effect generated by its high-speed rotation causes the foam drawn in from the center to gather along the wall and form liquid droplets, resulting in excellent foam elimination. The mid-level wide-blade paddle impeller is an axial flow type, possessing significant turbulent diffusion capability and lower shear force compared to traditional impellers. It can save 30%-40% of electricity and improve mass transfer coefficients by over 20% under the same power consumption. The bottom parabolic disc turbine impeller is a radial flow type with blade shapes of concave circular arc and parabolic surface, exhibiting strong radial displacement and dispersion capabilities. Under the same power, the mass transfer coefficient is 30% higher than that of traditional flat-blade disc turbine impellers, with a gas-holding capacity increased by over 40%.

By optimizing the combination of mixing impellers, Greatwall Mixers successfully met the requirements of the customer's project. This innovative solution not only increased production efficiency but also reduced energy consumption, bringing substantial economic benefits to the customer.

Greatwall Mixers is dedicated to providing customers with high-quality products and services. With advanced technology and extensive experience, Greatwall Mixers has established a good reputation in the field of biotechnology. In the future, the company will continue to innovate, providing customers with more outstanding solutions and driving the development of the biotechnology industry.